- 0531-87887788

來源:http://www.gbpeixun.com/ 發布時間:2024-02-27

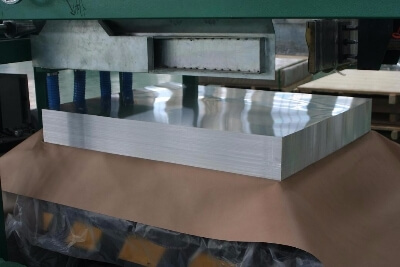

花紋鋁板屬于在鋁板的基礎上,經過壓延加工而在表面形成各種花紋的鋁產品,應用較為廣泛,主要用在包裝,建筑,幕墻等方面。那么,花紋鋁板拉絲的質量要如何檢測

Patterned aluminum plate is an aluminum product that forms various patterns on the surface through rolling processing on the basis of aluminum plate. It is widely used and mainly used in packaging, construction, curtain walls, and other aspects. So, how to detect the quality of patterned aluminum plate wire drawing

花紋鋁板

Patterned aluminum plate

標識的檢查:平常我們看到的花紋鋁板都是具有標識的,而且標識上是有產品的標準代號和許可證的。

Identification inspection: Usually, the patterned aluminum plates we see are labeled with the product's standard code and license.

氧化膜的厚度:這個是需要使用專業的渦流測厚儀器進行檢測。

The thickness of the oxide film: This requires the use of professional eddy current thickness measuring instruments for testing.

表面質量的檢查:在花紋鋁板的表面除了要看清潔與否之外,我們需要看到更多的東西,比如我們應該看看鋁板材是否出現了一些裂痕或者出現了一些腐蝕的現象,這些都是需要仔細的觀察的才能發現的。

Surface quality inspection: In addition to checking for cleanliness, we need to see more on the surface of patterned aluminum plates. For example, we should check if there are any cracks or corrosion on the aluminum plate, which requires careful observation to discover.

封孔質量酸浸法:封孔的形成是在進行的陽極氧化后才形成的,如果這些封孔沒有很好的處理的話,就會導致以后的鋁板材被腐蝕的現象出現。

Sealing quality acid immersion method: The formation of sealing holes is only after anodizing. If these sealing holes are not well treated, it will lead to corrosion of the aluminum plate in the future.

通常我們進行花紋鋁板拉絲拉絲的檢測方法是酸浸法,就是除去表面的灰塵之后,將硝酸滴到表面,進行輕輕的擦拭之后,用水洗掉硝酸,再在表面滴上紫藥水,一分鐘后搽干凈,看看表面是否有明顯的痕跡,如果有的話就說明封孔沒有處理的很好。

The usual method for testing patterned aluminum plate wire drawing is the acid immersion method. After removing the surface dust, nitric acid is dropped onto the surface, gently wiped, washed off with water, and then dropped purple solution on the surface. After one minute, it is wiped clean to see if there are any obvious marks on the surface. If there are any, it indicates that the sealing hole has not been treated well.